Complete Pumping Solutions

As the leading pump distributor and service provider in Saudi Arabia, we deliver end-to-end solutions, from supply and skid manufacturing to commissioning and lifecycle maintenance, ensuring reliability and value.

Building Saudi Arabia's Infrastructure Foundation

We provide complete pumping solutions through local manufacturing, expert maintenance, and reliable supply to ensure efficient fluid management across the Kingdom.

Overview

Alsuhaimi Pump Systems, a member of Alsuhaimi Group Holding, was formed in the 2000s and is a 100% Saudi-owned company based in Dammam. We serve as a trusted partner and local value-adder for the most reputed pump manufacturers in the world, including being one of the earliest distributors for Grundfos and Flowserve.

Our vision is to be a one-stop solution provider for pumps. Our Dammam facility is equipped for pump packaging, skid manufacturing, maintenance, and functional testing for pumps up to 150 kW. With a skilled team of service engineers, we provide expert field inspection, repair, and maintenance for pumps, motors, and control panels.

Services

Supply of Pumps for Various Applications

From domestic and building services to municipal networks and process duty, we source, size, and supply pumps that meet spec and schedule.

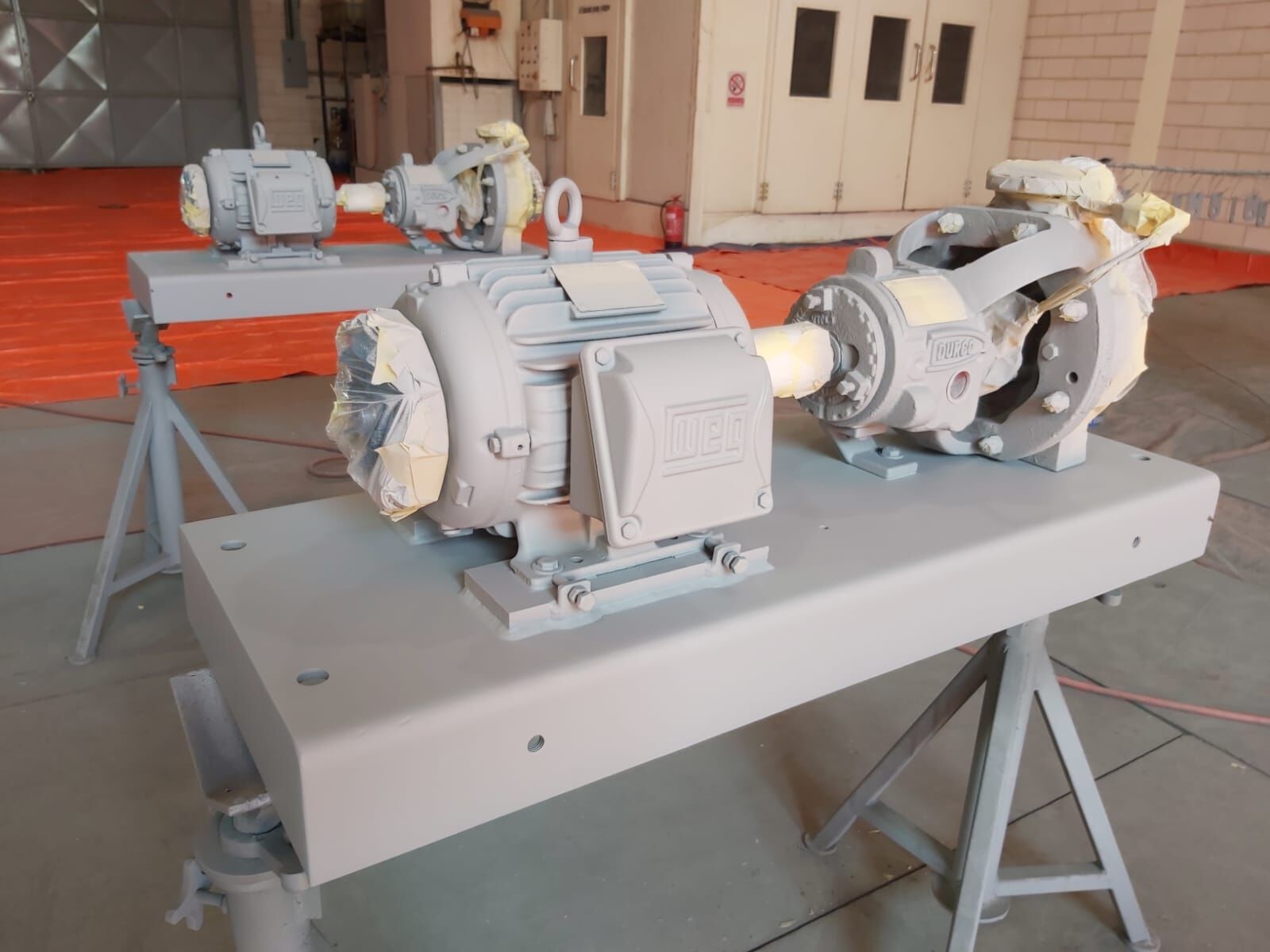

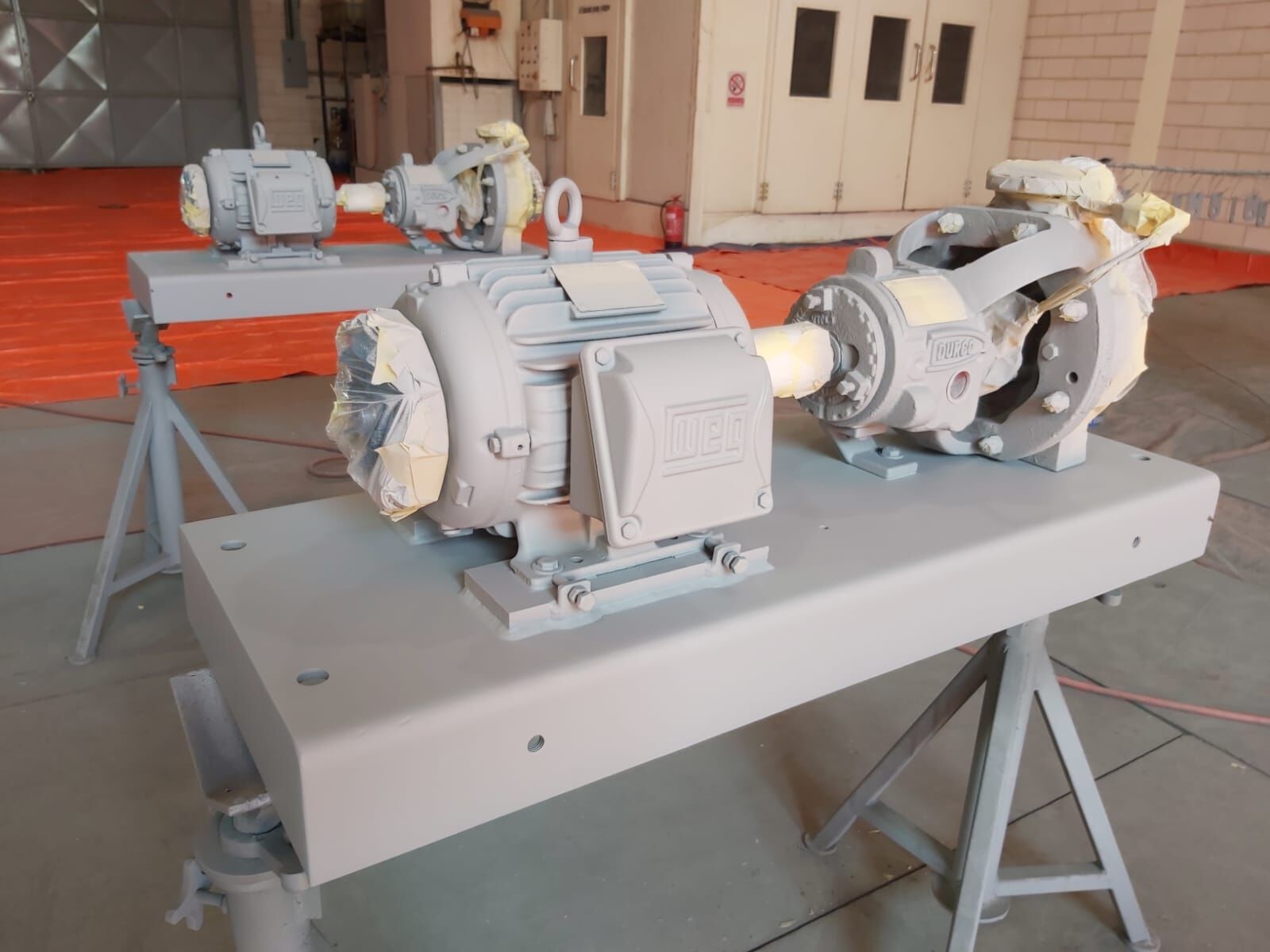

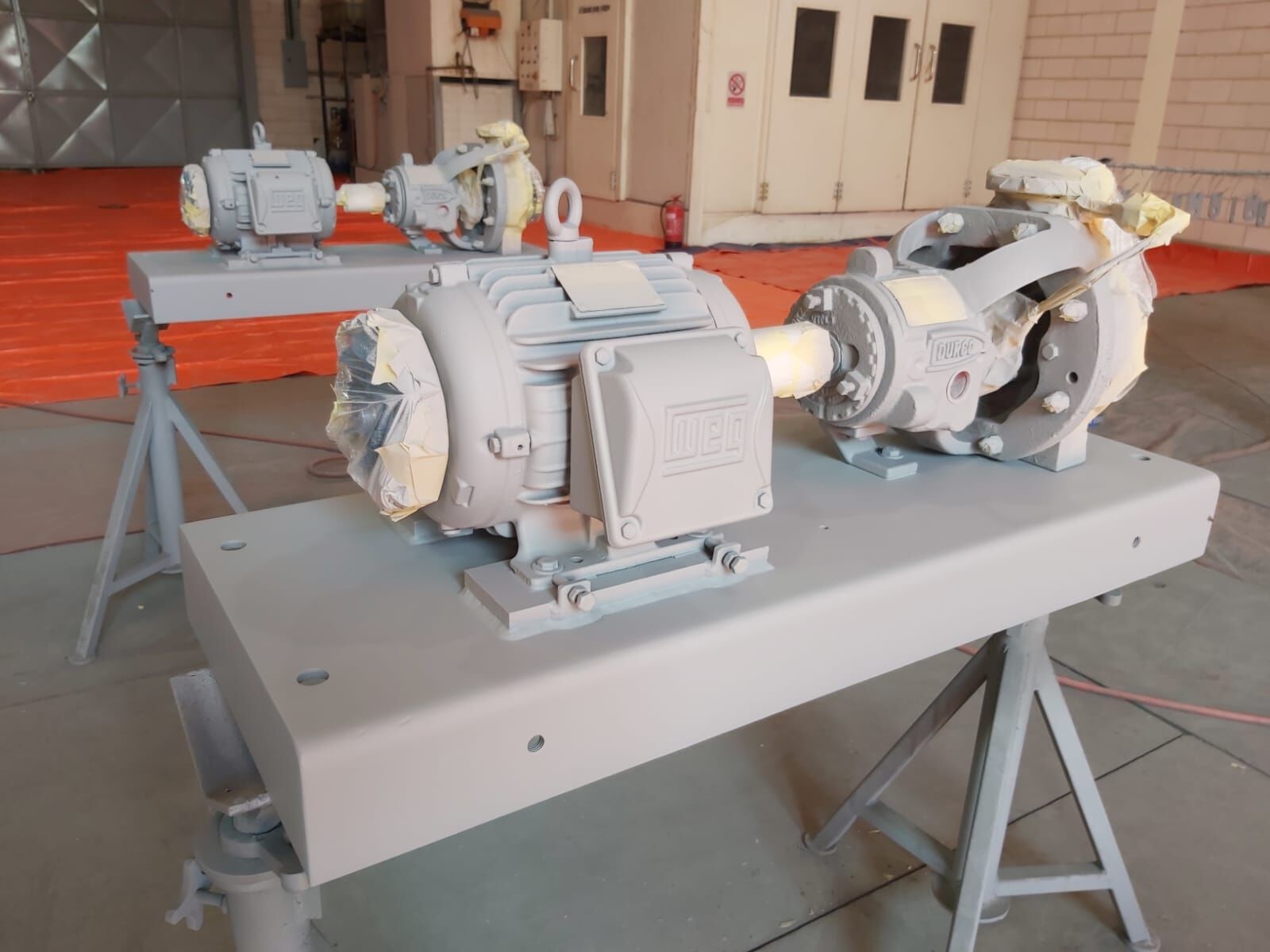

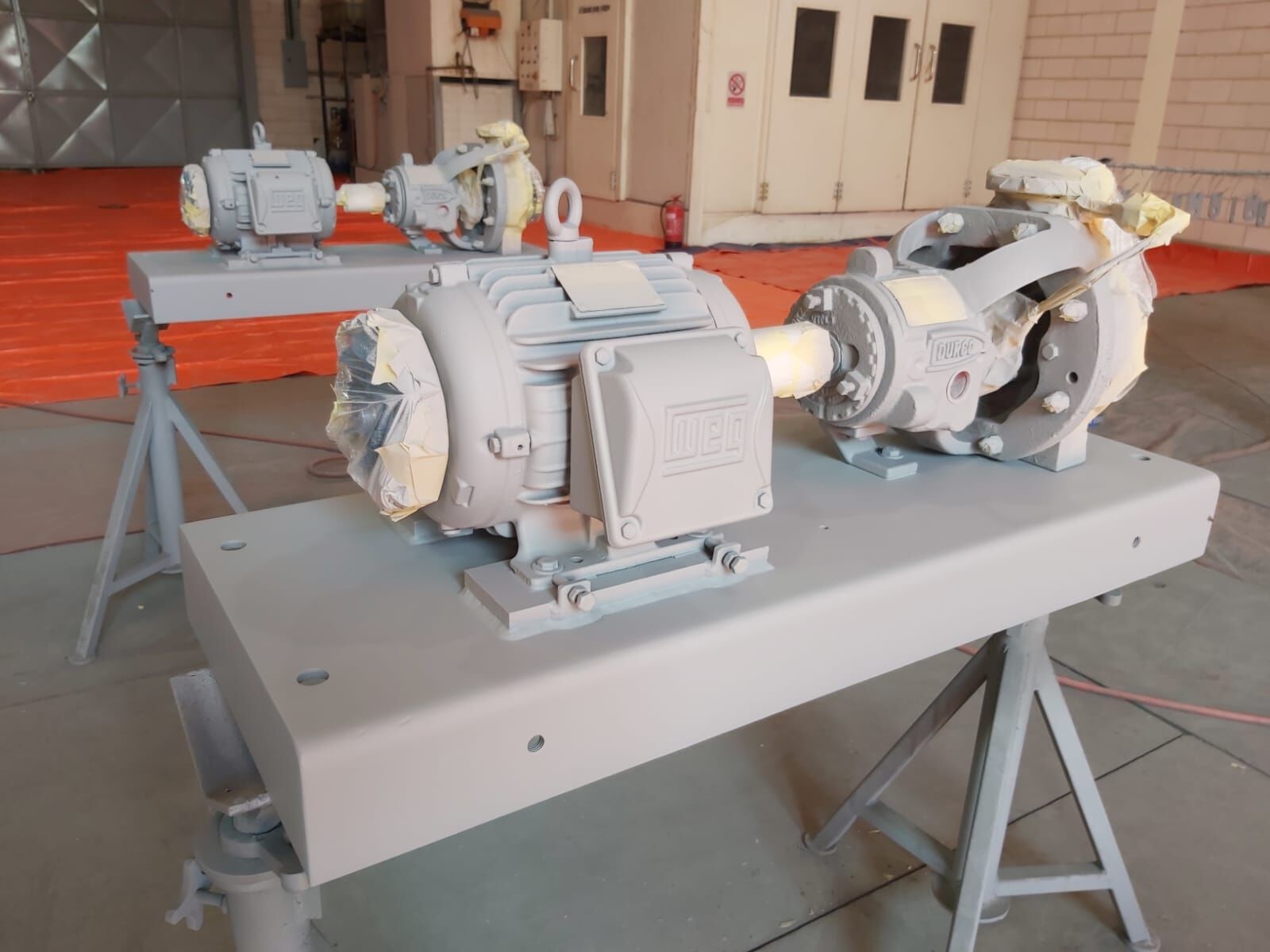

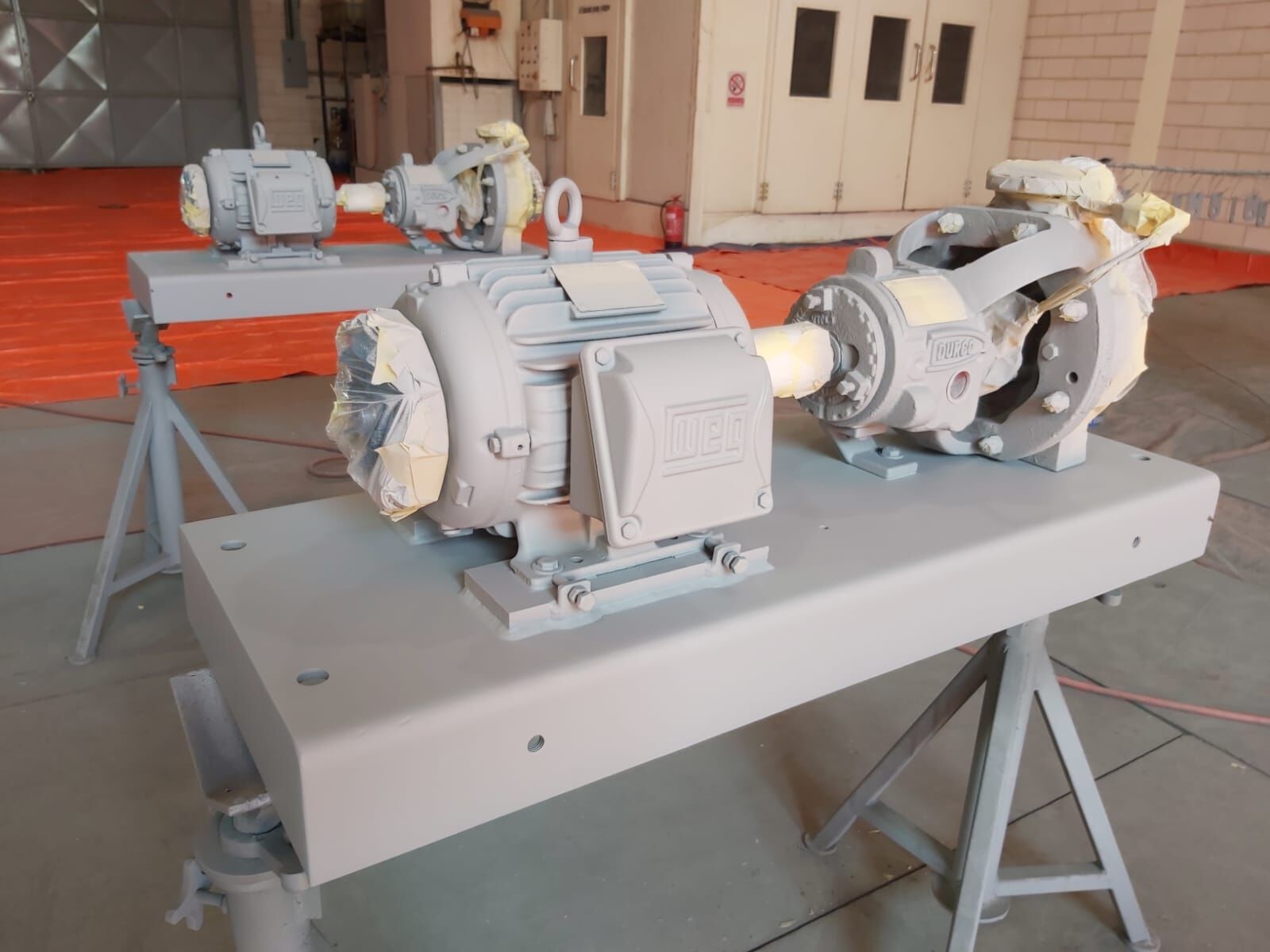

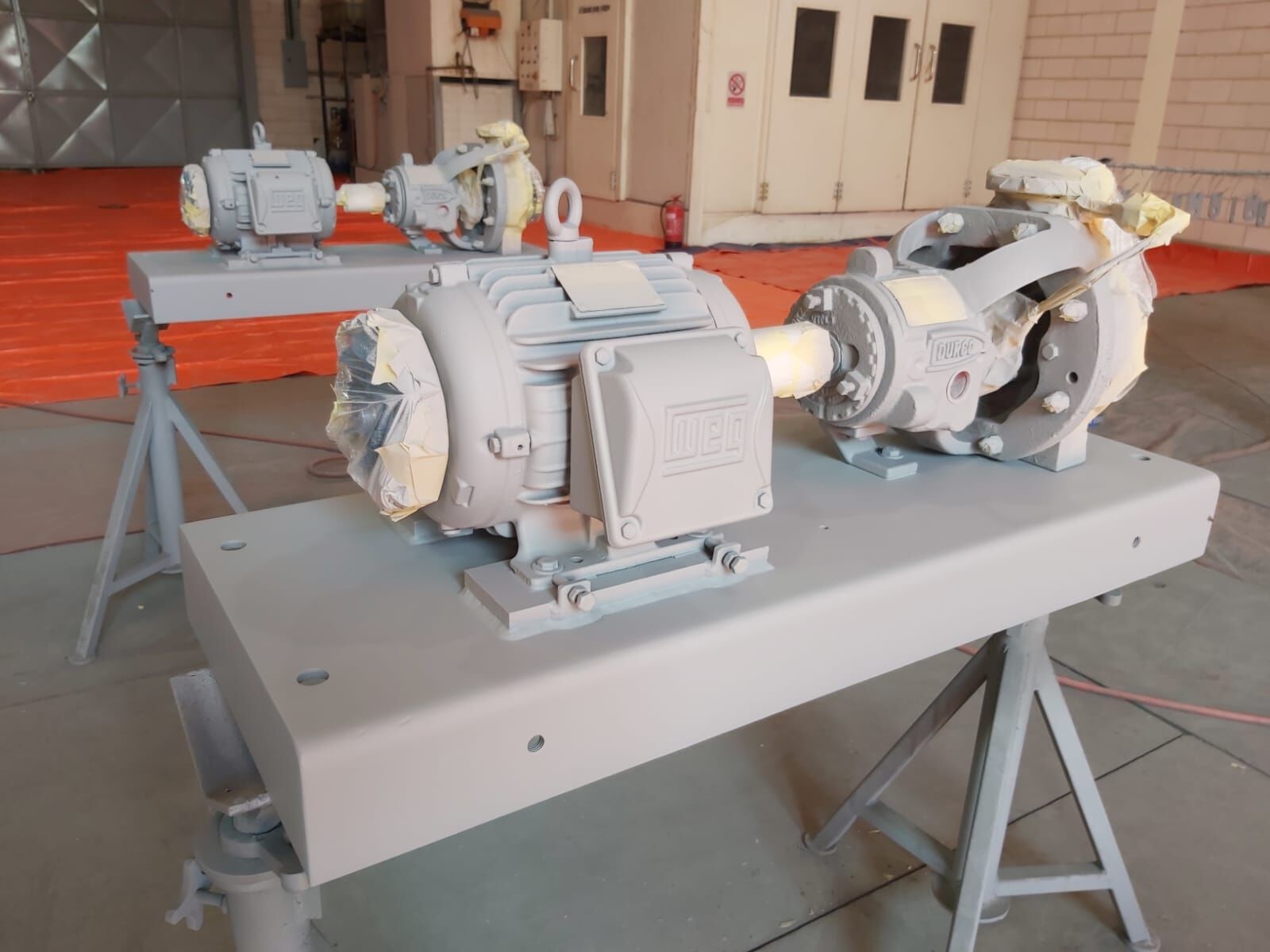

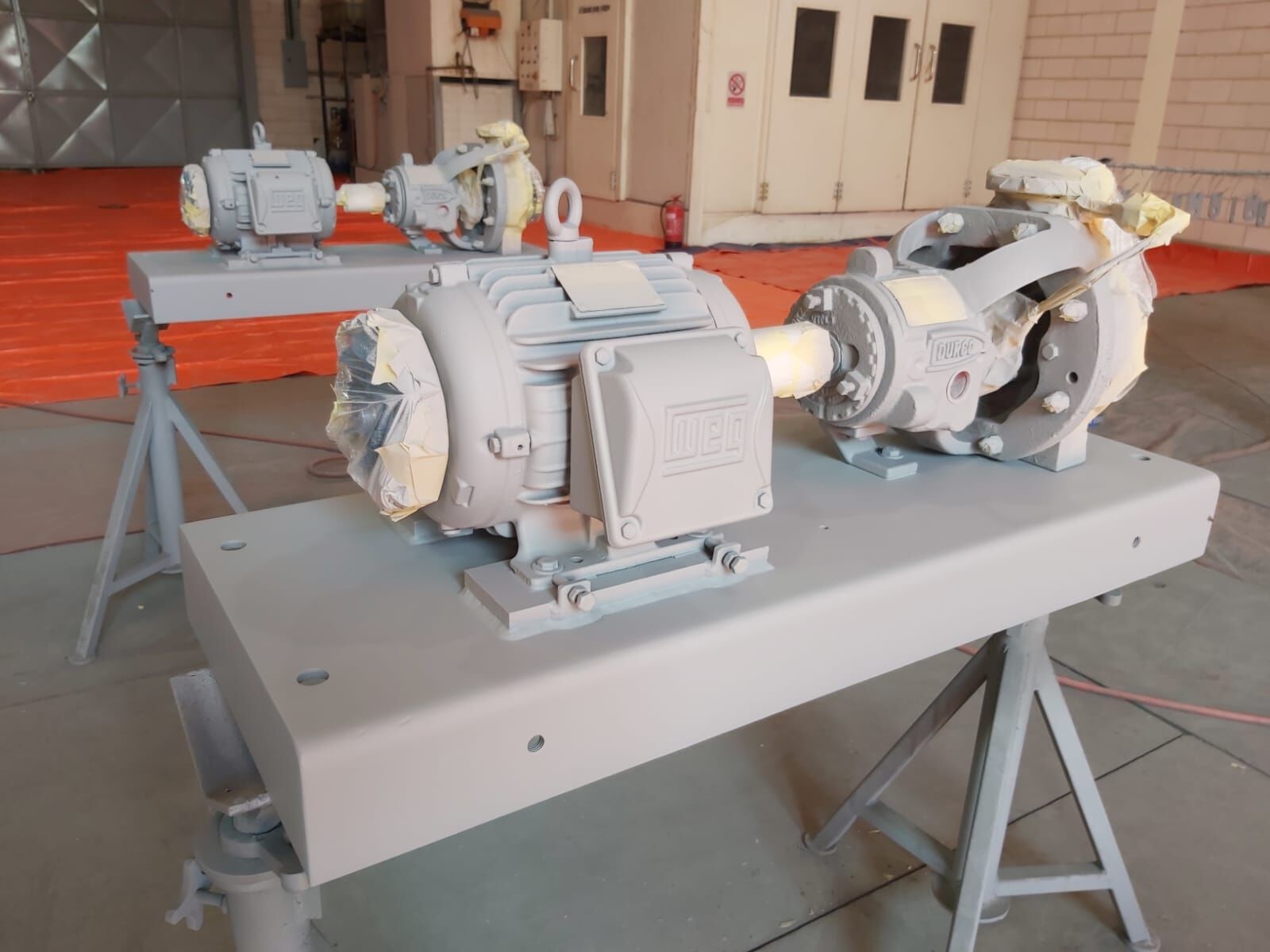

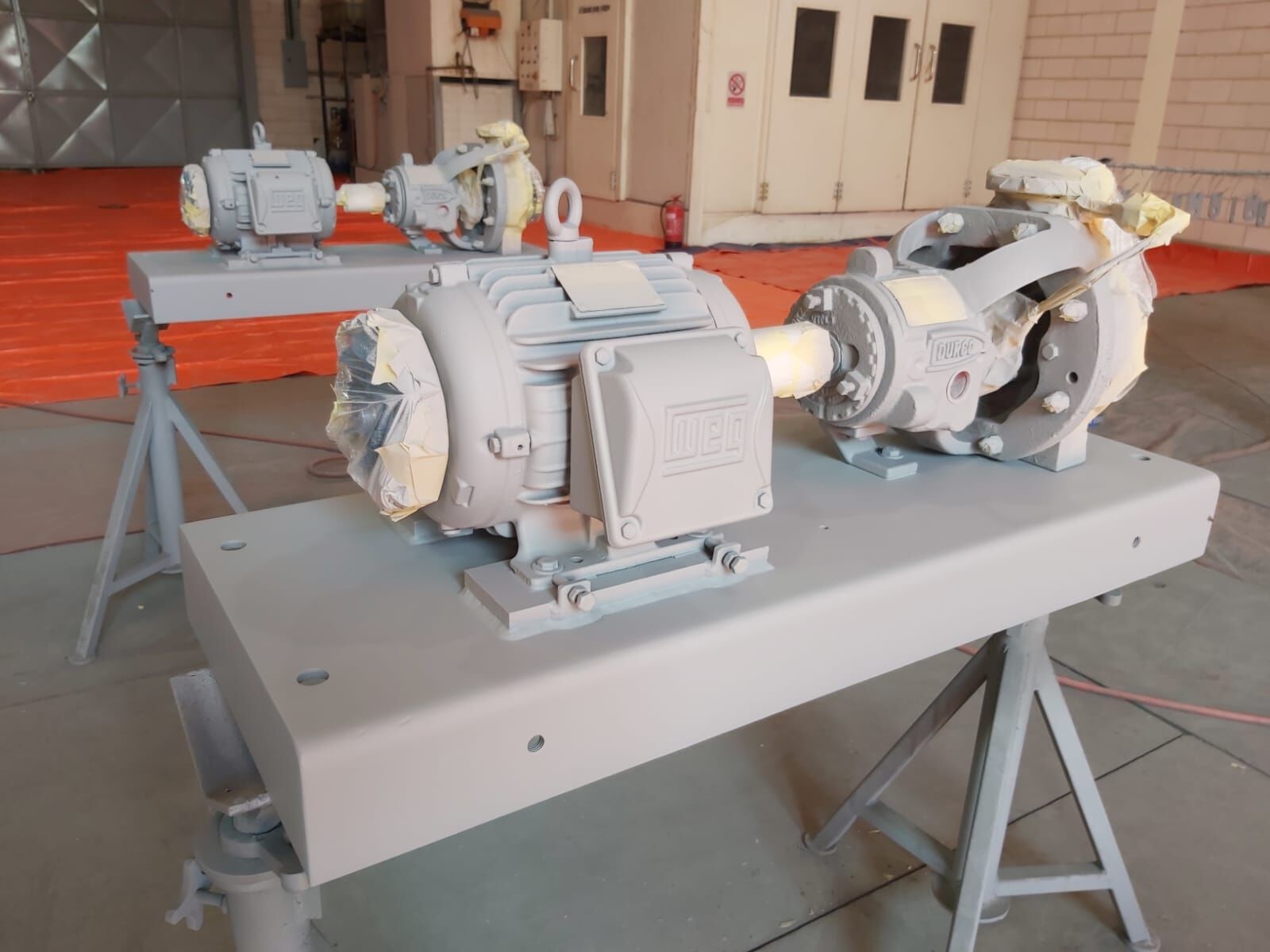

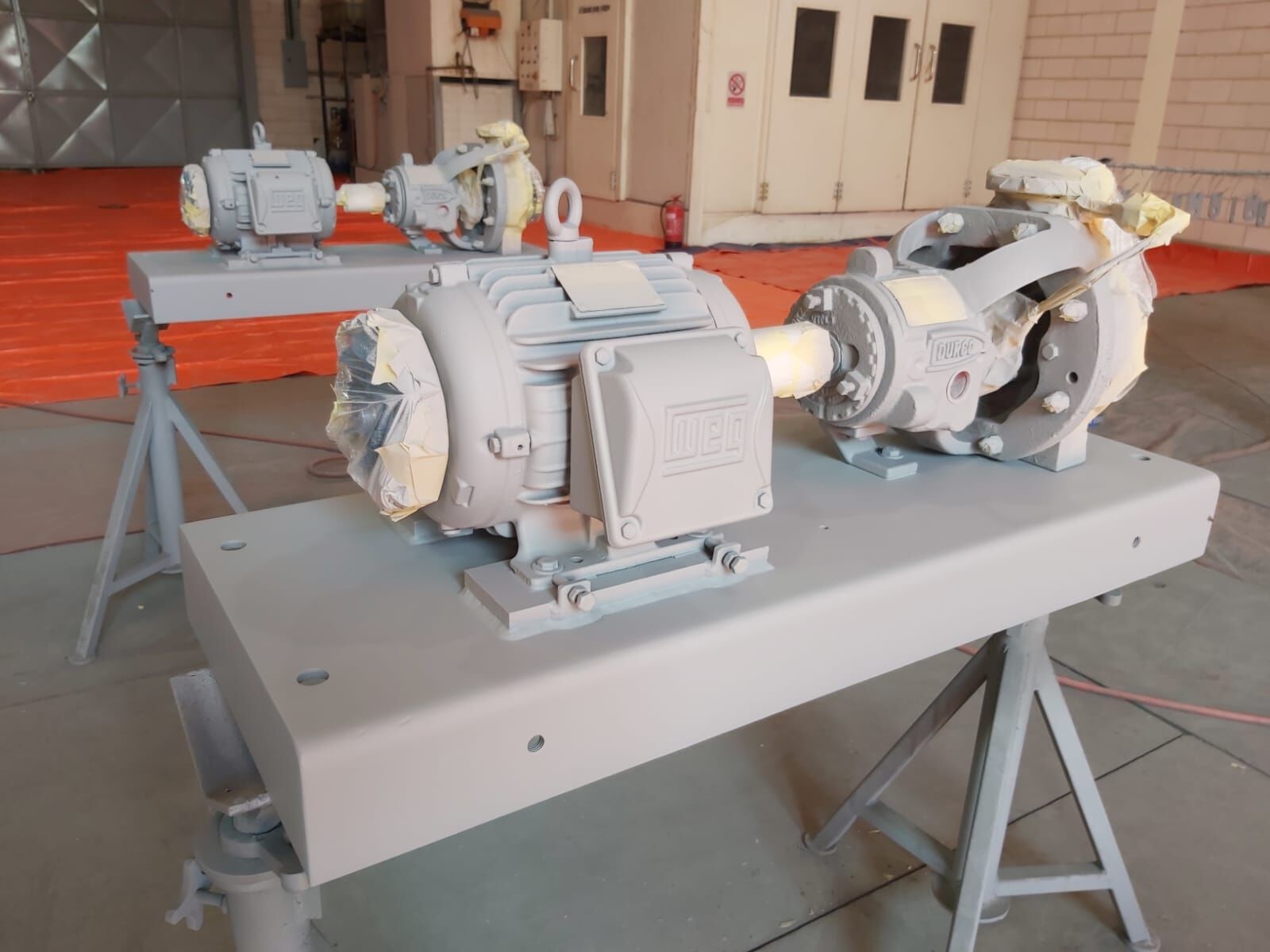

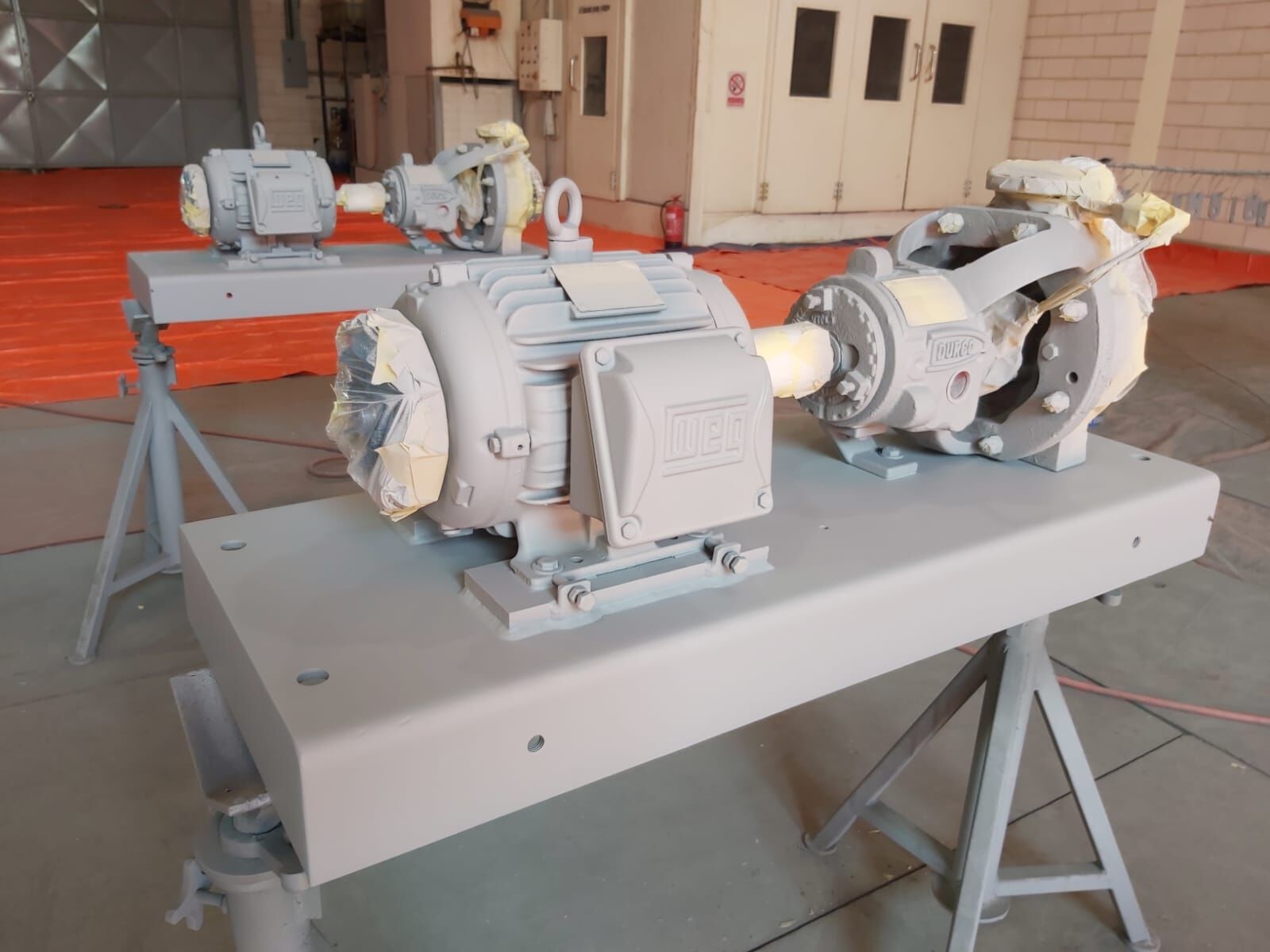

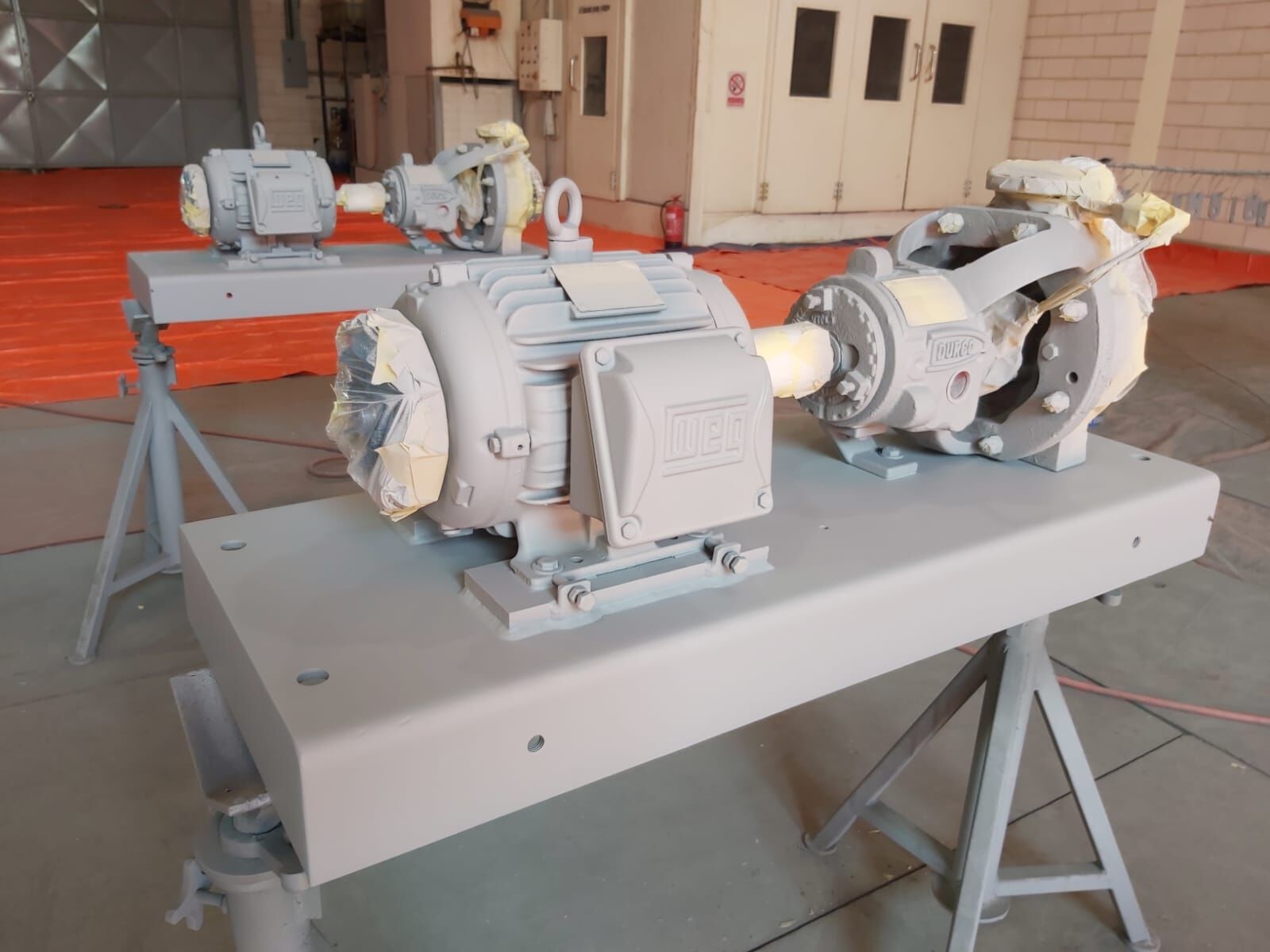

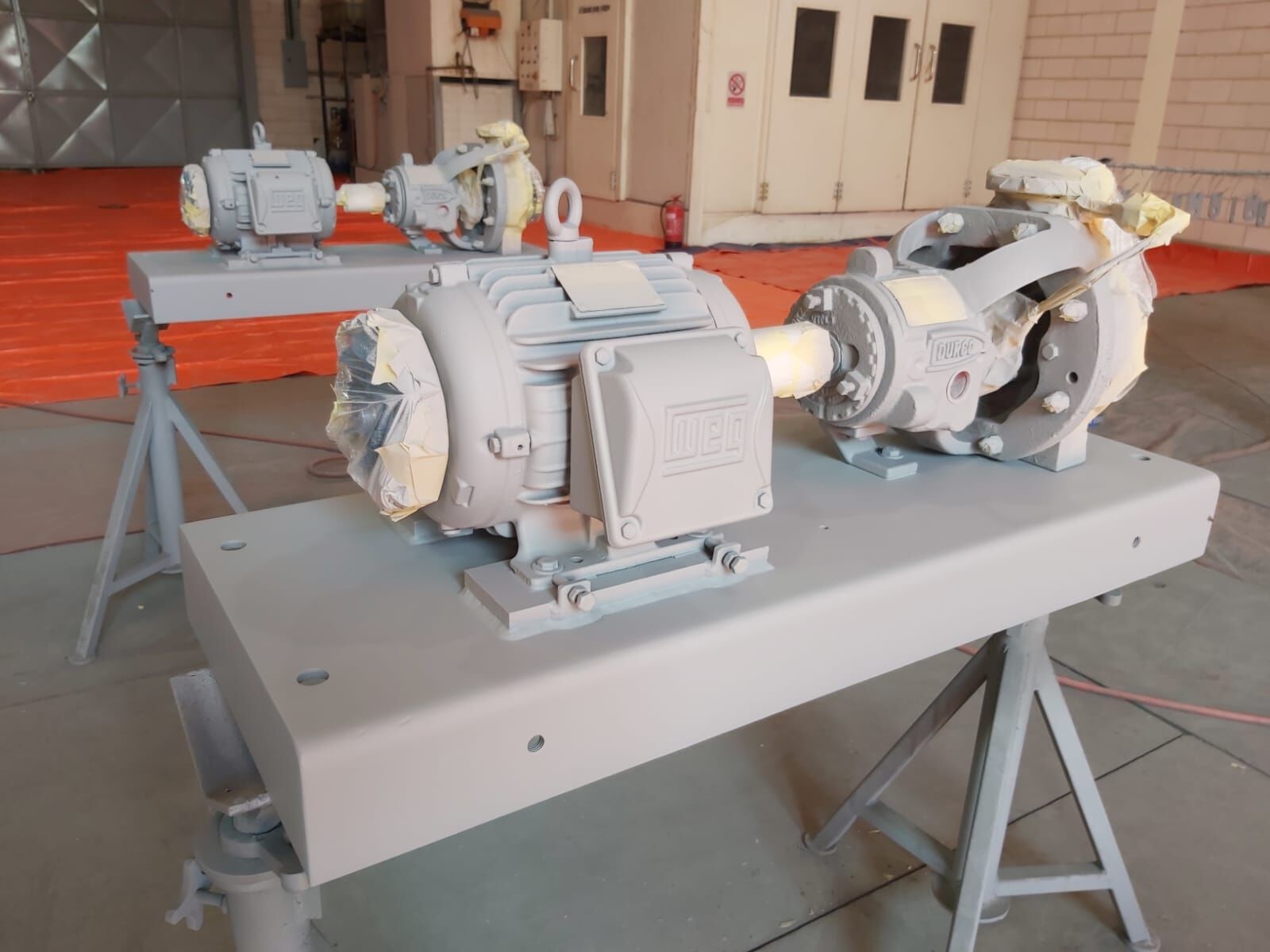

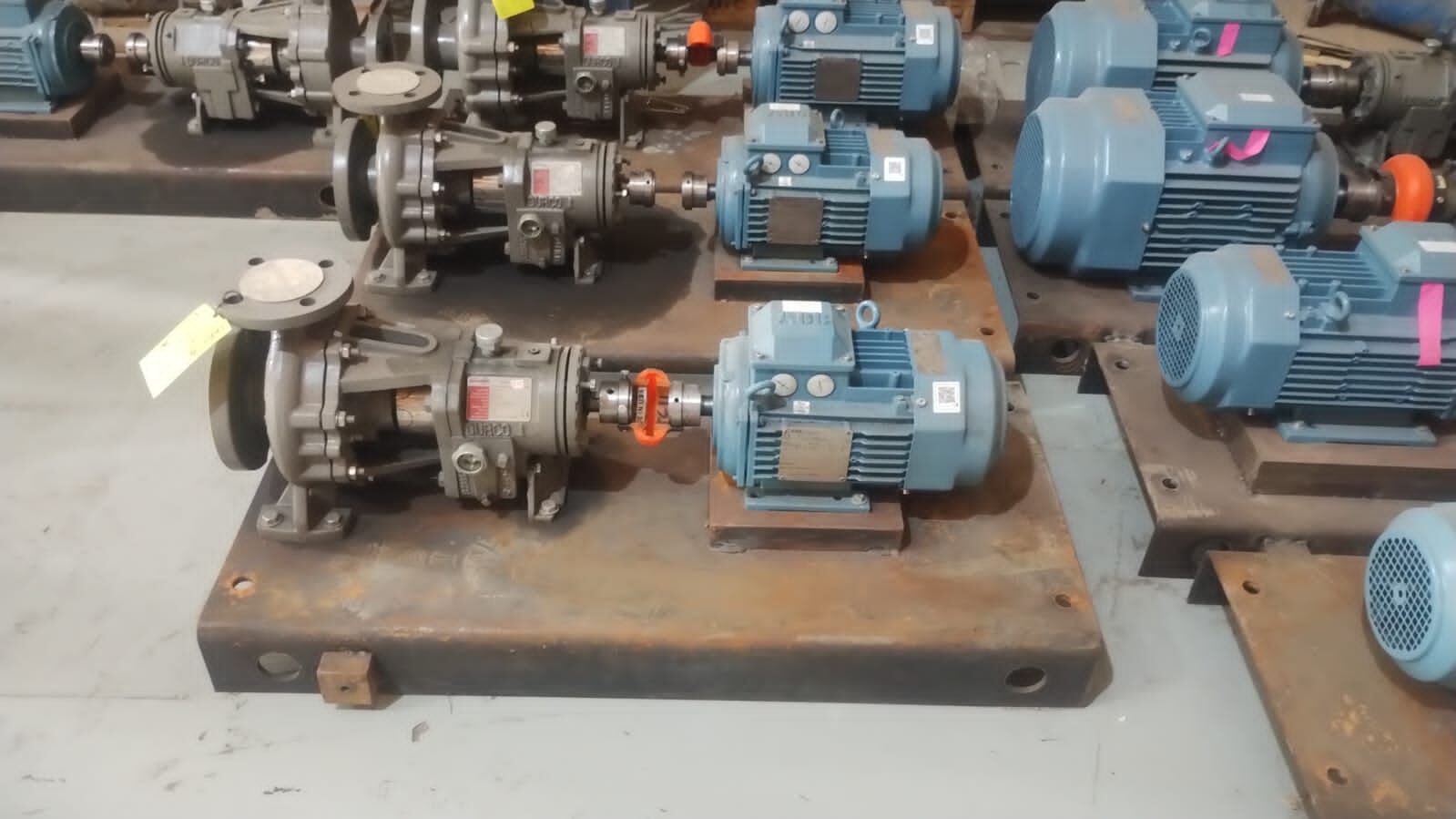

Fabrication of Skids, Value Addition & Packaging

We design and fabricate base frames, adaptor plates, pipe spools and fully packaged pump skids to integrate cleanly on site.

Alignment & On-site Skid Modifications

Retrofit and align existing skids to today’s standards with dial/laser alignment, spool mods and protective coatings.

Repair & Overhauling

From site startup and commissioning to in-house and on-site overhauls, our team restores uptime quickly and safely.

Control Panels & Electrical Expertise

Purpose-built control panels and VFD integrations with parameter tuning, troubleshooting and performance optimization.

Start-up & Commissioning

A structured start-up program that validates hydraulics, controls and protections so you hit spec on day one.

Capabilities

Engineering

- Team of Application and Design Engineers for technical solutions

- Expertise in designing customized pump skids and control panels

- Compliance with ANSI/API standards for Oil & Gas applications

Product Range

- Pumps for domestic water, building services, and chilled water

- UL listed / Non-UL Listed Fire Water Pump Sets

- Submersible borehole, wastewater, and non-metallic pumps for corrosive liquids

Controls & Panels

- Specialized solutions for DOL, Star-Delta (SD), and VFD driven pump sets

- Expertise in Variable Frequency Drive (VFD) parameter setting and function

- Field startup services and diagnosis of faults in Control Panels

Service & Testing

- Service facility in Dammam equipped for functional testing up to 150 kW

- Laser / Dial Gauge Alignment of pumps, motors, and components

- In-house and on-site pump overhauling with specialized tools

IndustriesWeServe

OurProcess

- 01Assess

Collect duty points, fluids, temperatures, codes and site constraints.

- 02Select

Hydraulic sizing and brand/model selection for efficiency and reliability.

- 03Package

Build skids with manifolds, valves, instruments and controls.

- 04Install

Set, align and connect; hydro/leak tests and pre‑start checks.

- 05Commission

Performance verification, documentation, training and handover.

- 06Support

Planned maintenance, troubleshooting and spare parts availability.

KeyPartners

Clients

Gallery

photos

photos

Projects

Completed

Jafurah GCP — Phase 1 (Initial Award)

For Aramco via L&T Hydrocarbon: 5× Grundfos SLV pump sets + accessories; 2× explosion-proof control panels (Pepperl & Fuchs). Delivered on time; fully compliant.

Jafurah GCP — Package 31

For same client/contractor: 7× SLV pump sets, 3× local control panels, 3× sensor panels + accessories; full testing & commercial compliance.

NEOM Green Hydrogen (Tabuk)

With Air Products: 4× Grundfos SLV pump sets + complete accessories; fully compliant; established strong working relationship.

Aramco — Pipeline Junction Security Upgrade

With SRACO: 4× booster skids (duty/standby pumps), VFD panels, pressure tanks, valves, instruments; design → manufacturing → testing → supply.

Zuluf Tanajib Project

For Aramco with Veolia: 8× Flowserve Chesapeake pump sets; fully integrated and compliant with testing & commercial requirements.

Water Improvement — South Strategic Network & Reservoirs

Contractor Al-Yamama; Consultant ILF; End user NWC: supply/delivery/testing/commissioning of horizontal centrifugal split case pump sets across Dammam & Jubail hubs.

Al Jubail Desalination — Phase 2 (SWA/SSEM)

12× Affetti chemical transfer/filling pumps + 2× Suhaimi control panels; plus Storm & Neutralization package: 37× SPP super duplex NS + accessories + 16 panels.

Water Improvement — South Strategic Network & Reservoirs (2)

Transmission & distribution reliability upgrades with packaged split-case pumps; full commissioning under consultant supervision.

Jafurah GCP — Phase 1 (Initial Award)

For Aramco via L&T Hydrocarbon: 5× Grundfos SLV pump sets + accessories; 2× explosion-proof control panels (Pepperl & Fuchs). Delivered on time; fully compliant.

Jafurah GCP — Package 31

For same client/contractor: 7× SLV pump sets, 3× local control panels, 3× sensor panels + accessories; full testing & commercial compliance.

NEOM Green Hydrogen (Tabuk)

With Air Products: 4× Grundfos SLV pump sets + complete accessories; fully compliant; established strong working relationship.

Aramco — Pipeline Junction Security Upgrade

With SRACO: 4× booster skids (duty/standby pumps), VFD panels, pressure tanks, valves, instruments; design → manufacturing → testing → supply.

Zuluf Tanajib Project

For Aramco with Veolia: 8× Flowserve Chesapeake pump sets; fully integrated and compliant with testing & commercial requirements.

Water Improvement — South Strategic Network & Reservoirs

Contractor Al-Yamama; Consultant ILF; End user NWC: supply/delivery/testing/commissioning of horizontal centrifugal split case pump sets across Dammam & Jubail hubs.

Al Jubail Desalination — Phase 2 (SWA/SSEM)

12× Affetti chemical transfer/filling pumps + 2× Suhaimi control panels; plus Storm & Neutralization package: 37× SPP super duplex NS + accessories + 16 panels.

Water Improvement — South Strategic Network & Reservoirs (2)

Transmission & distribution reliability upgrades with packaged split-case pumps; full commissioning under consultant supervision.

Ongoing / In Progress

Jafurah GCP — Package 21 (In Progress)

For Aramco via L&T Hydrocarbon: 8× SLV pump sets, cranes, conduits, trays, spares + 4× explosion-proof control panels; fully compliant.

Al Jubail Desalination — Phase 2 (Ongoing)

22× Grundfos SL/SLV/SEG with 11× Suhaimi control panels (sewage & oily water); NaOH system: 2× SPP + motors (Marathon/WEG) + 1 panel.

Qatif Booster Station — O₂ Pumps Replacement (G-13 & G-14)

For Aramco via DMZCO: 2× Flowserve pump sets with 1300 HP Nidec motors; full testing & commercial compliance.

Qatif — Raw Water Pump Replacement (18-G-12)

For Aramco via QYD Arabia: 1× Flowserve pump set with 1300 HP Nidec motor; full compliance.

Zuluf Industrial Support (In Progress)

For Aramco with Veolia: 10× complete pump sets — Flowserve Spain pumps, ABB Finland motors, Suhaimi-fabricated skids; fully compliant.

Al Jubail Desalination — Phase 2 (Potable & Service Water Skids)

For SWA with Trillium: 2× complete skids (SPP pumps, Siemens motors, ABO valves, skid fabrication, control panels & final assembly).

Jafurah GCP — Package 21 (In Progress)

For Aramco via L&T Hydrocarbon: 8× SLV pump sets, cranes, conduits, trays, spares + 4× explosion-proof control panels; fully compliant.

Al Jubail Desalination — Phase 2 (Ongoing)

22× Grundfos SL/SLV/SEG with 11× Suhaimi control panels (sewage & oily water); NaOH system: 2× SPP + motors (Marathon/WEG) + 1 panel.

Qatif Booster Station — O₂ Pumps Replacement (G-13 & G-14)

For Aramco via DMZCO: 2× Flowserve pump sets with 1300 HP Nidec motors; full testing & commercial compliance.

Qatif — Raw Water Pump Replacement (18-G-12)

For Aramco via QYD Arabia: 1× Flowserve pump set with 1300 HP Nidec motor; full compliance.

Zuluf Industrial Support (In Progress)

For Aramco with Veolia: 10× complete pump sets — Flowserve Spain pumps, ABB Finland motors, Suhaimi-fabricated skids; fully compliant.

Al Jubail Desalination — Phase 2 (Potable & Service Water Skids)

For SWA with Trillium: 2× complete skids (SPP pumps, Siemens motors, ABO valves, skid fabrication, control panels & final assembly).

Certificates

Contact

Get in Touch!

Address

EMPB7521, Dammam, K.S.A